Leave Your Message

-

CONTACT WhatsApp

CONTACT WhatsApp -

-

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT EMAIL

CONTACT EMAIL

Nonwoven For Medical Fabric has transformed healthcare. These fabrics provide essential solutions, offering safety and reliability. The increasing demand for hygiene in medical settings drives innovation in this sector.

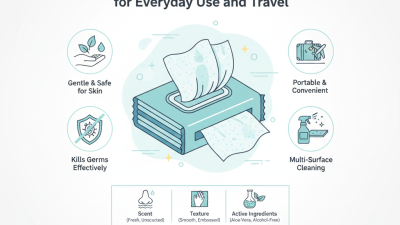

Medical applications require specific attributes. Nonwoven fabrics are lightweight, breathable, and absorbent. They help minimize infection risks effectively. However, choosing the right nonwoven material can be challenging. With so many options available, understanding the distinct properties is crucial.

While nonwoven fabrics offer benefits, there are areas for improvement. Sustainability remains a pressing issue. Some materials may not be eco-friendly. Manufacturers must prioritize research to enhance performance while considering environmental impact. As the market evolves, it is vital to reflect on the balance between functionality and sustainability in Nonwoven For Medical Fabric.

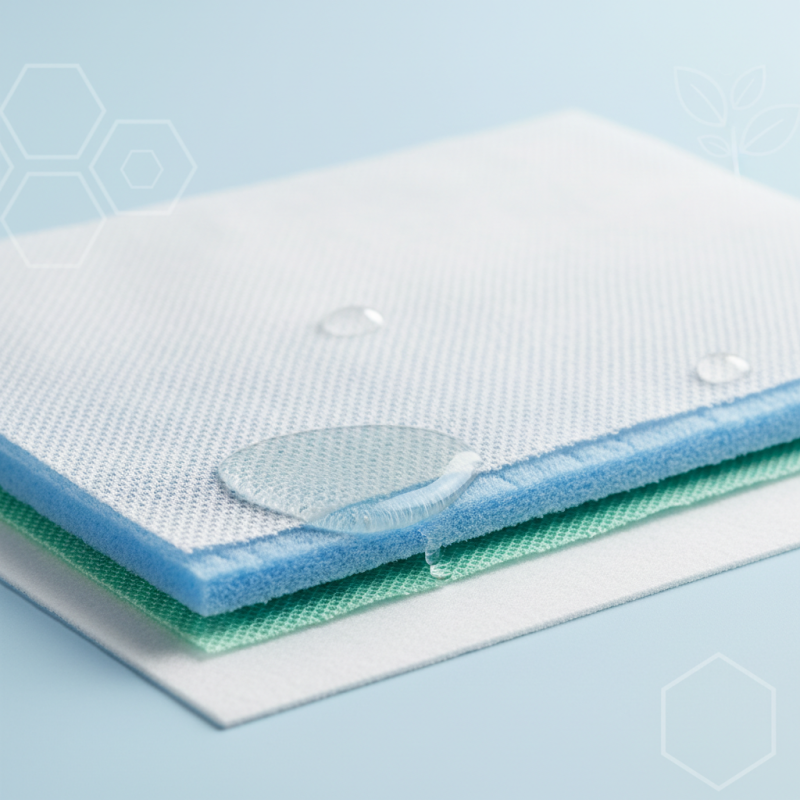

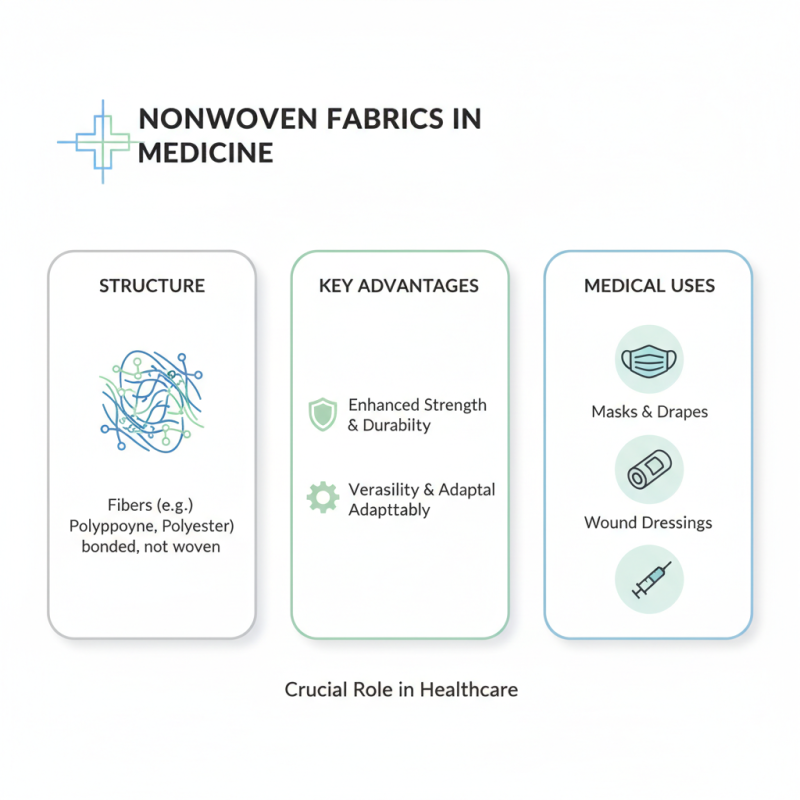

Nonwoven fabrics play a crucial role in medical applications. Their unique structure allows a wide range of uses in the healthcare sector. They are created by bonding fibers, which can be made from various materials like polypropylene and polyester. This process enhances their strength and versatility compared to woven fabrics.

There are several types of nonwoven fabrics, including spunbond, meltblown, and needlepunch. Spunbond fabrics, known for their durability, often serve in surgical gowns and drapes. Meltblown nonwovens are preferred for filtration, making them suitable for masks and respiratory products. A recent report from Smithers Pira states that the global nonwoven fabric market will reach $50 billion by 2025, driven by increasing demand in medical and hygiene sectors.

However, not all nonwoven solutions are flawless. The environmental impact of single-use medical fabrics raises concerns. Many nonwoven products are disposed of after one use, contributing to landfill waste. Innovating sustainable alternatives is essential. Balancing performance and environmental responsibility remains a challenge in this evolving industry.

Nonwoven fabrics play a crucial role in medical applications. Their unique properties make them ideal for various uses, from surgical gowns to face masks. According to a report by MarketsandMarkets, the global nonwoven fabric market in the medical sector is projected to reach $20 billion by 2025. This indicates a steady growth driven by demand for hygiene products and infection control.

A key property of nonwoven fabrics is their fluid resistance. These materials can repel bodily fluids effectively, ensuring that medical staff remain safe. Additionally, breathability is vital. Nonwoven fabrics allow air circulation, enhancing comfort during long procedures. Furthermore, their lightweight nature adds to usability. However, not all nonwoven fabrics offer the same protection levels. It's essential to choose the right fabric based on specific applications.

**Tip:** Always check the fabric's specifications before making a selection. Certifications can indicate the level of protection offered. Another important factor is the fabric's durability. Nonwoven fabrics vary in strength, impacting their effectiveness during use. While some are designed for single-use, others can withstand multiple wash cycles. Be mindful of these aspects while sourcing materials for medical applications.

| Property | Description | Importance in Medical Use |

|---|---|---|

| Biocompatibility | The ability of a material to perform its desired function without eliciting an inappropriate response from the body. | Essential for preventing adverse reactions when used in medical applications. |

| Barrier Properties | Resistance to penetration by bacteria, fluids, and particulates. | Critical for surgical gowns, masks, and drapes to ensure patient and healthcare worker safety. |

| Fluid Resistance | The ability of the fabric to repel liquids. | Important for items like surgical attire that need to keep fluids from permeating. |

| Air Permeability | The measure of how easily air can pass through the fabric. | Ensures comfort in medical garments while maintaining protective functions. |

| Strength | The durability and tensile strength of the fabric material. | Necessary for ensuring the integrity of the fabric under stress and during use. |

| Softness | The tactile feel of the fabric against the skin. | Enhances patient comfort, especially in extended wear scenarios. |

| Eco-Friendliness | The environmental impact of the fabric's production and disposal. | Key for sustainability in the healthcare industry. |

In the realm of medical applications, nonwoven fabrics play a vital role. Many industry standards govern their use. Organizations like ASTM International and ISO set rigorous guidelines. These standards ensure safety and effectiveness. For instance, ASTM F1862 evaluates blood penetration resistance. Compliance boosts provider confidence in nonwoven products.

Certifications add another layer of credibility. Products often require CE marking or FDA approval. These certifications attest to quality and safety. A study by Smithers shows that 73% of manufacturers prioritize compliance with standards. However, achieving these certifications can be a lengthy process. Many companies face challenges meeting all requirements.

Manufacturers must remain vigilant. Continuous improvement is essential. Market demands shift rapidly. New materials and technologies emerge frequently. Not all nonwovens will pass stringent testing. The journey toward compliance is often complex. Striving for better solutions is necessary for all stakeholders involved.

Emerging trends in nonwoven fabric technology are transforming healthcare applications. These fabrics are lightweight, breathable, and customizable. They are crucial in creating medical products, such as masks and gowns. Recent advances focus on enhancing barrier properties for better protection. Some developments have introduced biodegradable options. This shift targets environmental concerns, aiming for more sustainable solutions.

Another exciting trend is the integration of antimicrobial properties. This makes nonwoven fabrics safer for patients and healthcare workers. Researchers are exploring innovative additives to improve hygiene. However, ensuring longevity while maintaining these properties is challenging. Some products lose effectiveness over time, raising questions about reliability.

Additionally, smart technologies are being integrated into nonwoven fabrics. Wearable sensors can monitor vital signs or detect infections. Although this concept is still in its infancy, the potential is vast. Experts are investigating how these fabrics can support remote patient monitoring. Yet, balancing complexity with usability remains a significant hurdle. The future of nonwoven fabrics in healthcare is bright but requires careful consideration and ongoing development.

The medical nonwoven fabric market is expected to experience significant growth. According to a recent report by Grand View Research, the market is projected to reach USD 20 billion by 2025, with a CAGR of over 5%. This growth is driven by rising demand from the healthcare sector, particularly for hygiene products and surgical materials. Nonwoven fabrics are favored for their light weight, flexibility, and cost-effectiveness.

One of the key factors contributing to this trend is the increase in healthcare-associated infections (HAIs). Nonwoven materials provide excellent barrier properties, making them ideal for medical applications such as gowns, masks, and drapes. A study by Smithers Pira estimates that over 60% of all surgical masks are now made from nonwoven materials. This shift indicates a need for innovation and improvement in material quality to meet safety standards.

Despite the promising growth, challenges remain. Quality control in production processes needs attention. Nonwovens can vary greatly in performance and effectiveness, raising concerns among professionals. The industry's focus on sustainability adds another layer of complexity, as sourcing eco-friendly raw materials becomes increasingly critical. Balancing these demands will be essential for stakeholders in the medical nonwoven market.