Leave Your Message

-

CONTACT WhatsApp

CONTACT WhatsApp -

-

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT EMAIL

CONTACT EMAIL

Choosing the right non woven material for your projects can be challenging. The sheer variety of options may overwhelm you. Non woven material comes in different textures, weights, and colors. Each option serves unique purposes, making the choice significant for your project’s success.

Consider the specific requirements of your project. For example, some non woven materials are soft and breathable, while others offer durability and water resistance. Reflect on the desired look and feel of your finished product. Sometimes, the ideal material might not be immediately obvious.

It’s also essential to evaluate the environmental impact. Some non woven materials are more eco-friendly than others. Balancing quality with sustainability can be difficult but is often necessary. Don't hesitate to experiment with samples and gather feedback. This approach often reveals insights that catalogs cannot. Ultimately, the right choice will depend on examining both the practical and aesthetic aspects as you navigate the selection process.

Non woven materials are versatile and widely used in various projects. They are made from fibers that are bonded together, often through heat, chemical, or mechanical processes. These materials offer unique qualities, making them ideal for applications in agriculture, medical supplies, and construction. Understanding the specific properties of non woven materials is crucial for making the right choice.

When selecting non woven fabric, consider its intended use. For example, if used in gardening, opt for UV resistant varieties. These will withstand the sun's harsh rays. For medical applications, select materials with antimicrobial properties. This can enhance safety and effectiveness.

**Tips:** Always test a small sample before full-scale use. This can save time and resources. Also, be aware that some non woven materials may not perform well under extreme conditions. Regular reviews of your choices can lead to better outcomes. A thoughtful approach ensures a better fit for your projects.

This chart illustrates the different types of non woven materials and their applications based on usage in various industries.

When choosing non woven materials, understanding their types is crucial. There are several options available, each suited for different projects. For instance, spunbond fabric is popular for its durability. It's often used in reusable shopping bags and medical supplies. Its lightweight nature makes it easy to work with, yet it can sometimes feel less sturdy than expected.

Another option is needle-punched non woven fabric. This type is created by entangling fibers through mechanical means. It’s commonly used in automotive applications and geotextiles. The texture can be rough, which might not be ideal for all aesthetic projects. Sometimes, the finish can look less polished, indicating a need for careful selection based on the intended use.

Hydroentangled fabrics are also worth considering. These materials are softer and often used in wipes and hygiene products. Their delicate feel offers a great advantage, but they can struggle with durability under heavy use. Project goals should dictate the choice; aesthetics versus function can create tension in the decision-making process. Each type of non woven material brings its strengths and weaknesses, demanding mindful evaluation.

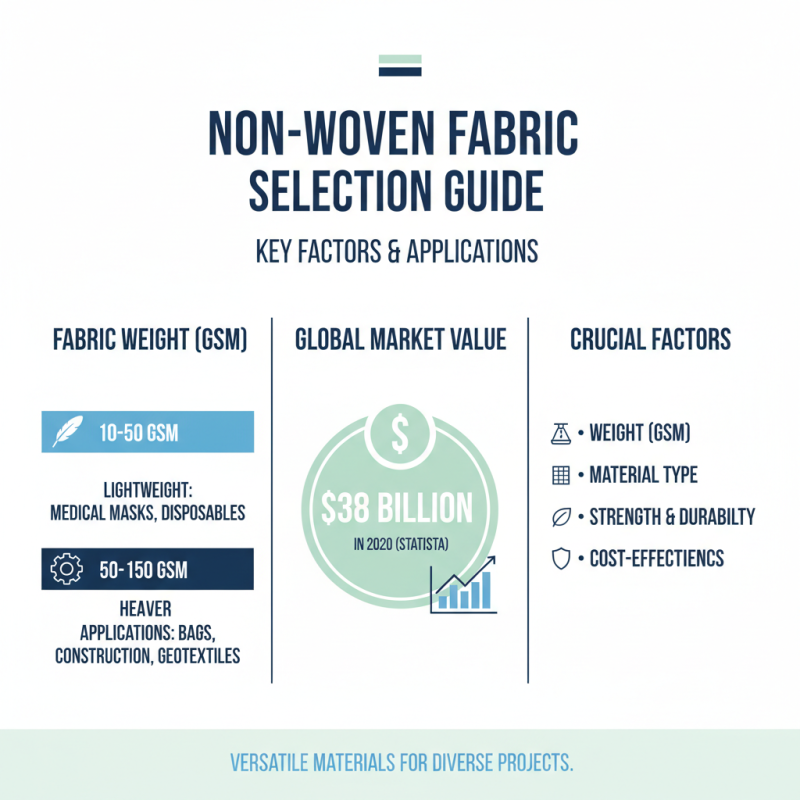

When selecting non-woven materials for your projects, several factors are crucial. The weight of the fabric plays a significant role. It is measured in grams per square meter (gsm). Light-weight non-woven fabrics typically range from 10 to 50 gsm, ideal for applications like medical mask production. Heavier variants, from 50 to 150 gsm, provide durability for items such as bags or construction materials. According to Statista, the global non-woven fabric market was valued at approximately $38 billion in 2020, underscoring the material’s growing importance in various industries.

The type of fiber used also matters. Polyester and polypropylene are common choices. Polyester offers good elasticity and exceptional resistance to moisture. On the other hand, polypropylene is known for its cost-effectiveness and lightweight properties. Reports indicate that polypropylene accounted for over 60% of non-woven fabric production in 2022. However, evaluating the environmental impact is essential. Some fabrics may not be recyclable, which could pose issues for sustainability-minded projects. This raises the question: are we prioritizing functionality over eco-friendliness?

Lastly, consider the intended application. Non-woven materials can vary widely in texture and feel. For instance, softer non-woven fabrics work well in hygiene products, while stiffer materials suit construction uses. It’s vital to test samples before making a final decision. Ensuring the material fits the specific needs of your project can save time and resources in the long run. Balancing functionality with environmental impact remains a constant challenge for designers and manufacturers alike.

Non woven materials are versatile and widely used across various industries. In healthcare, they serve critical functions. For instance, disposable surgical masks and gowns made from non woven fabrics offer protection and hygiene. These items are lightweight and easy to dispose of, but their effectiveness relies on proper use and disposal methods. Sometimes, failed adherence to such practices can lead to contamination.

In the fashion industry, non woven materials are often used for linings and interfacings. They are lightweight and easy to manipulate. Design choices can enhance the final product, yet not all fabrics offer the same durability. Designers must carefully evaluate their options to avoid premature wear or damage. Moreover, sustainability remains a concern; many non woven fabrics are not biodegradable and can impact the environment.

Additionally, non woven materials find usage in agriculture. Growers utilize these fabrics for weed control and plant protection. The right material can promote healthy growth by allowing air and moisture through. However, selecting the wrong type may create a barrier that stunts plant development. It’s important for users to assess their specific requirements and make informed decisions.

When sourcing quality non woven fabrics, understanding material specifications is essential. Non woven fabrics have various properties that affect performance. For instance, spunbond fabrics offer high strength, while meltblown types excel in filtration applications. According to recent industry reports, the global non woven fabric market size was valued at over $30 billion in 2022, with an expected growth rate of 6% annually. This highlights the rising importance of these materials.

Consider the intended use of the non woven fabric. Whether it’s for medical, hygiene, or agricultural applications, each category demands specific qualities. The right choice could impact product effectiveness. Not all suppliers maintain strict quality control standards. Researching potential suppliers can save time and avoid issues. Some products may not meet durability expectations. Reading reviews and demanding samples can help in evaluating quality.

Pricing can fluctuate, influenced by material type and market demand. It’s wise to compare prices across suppliers, but don’t compromise on quality for lower costs. An initial saving might lead to higher costs down the line if issues arise. Remember that effective sourcing is about balancing quality and cost, not just chasing the lowest price. Always keep an open dialogue with manufacturers to clarify specifications and expectations.

| Material Type | Weight (gsm) | Thickness (mm) | Applications | Key Features |

|---|---|---|---|---|

| Spunbond | 30-150 | 0.4-0.8 | Bags, Medical, Geotextiles | Breathable, Lightweight, Chemical Resistant |

| Needle Punch | 100-300 | 1.0-3.0 | Carpets, Filters, Insulation | Durable, High Absorption, Thermal Insulation |

| Chemical Bonded | 40-200 | 0.5-2.0 | Hygiene Products, Wipes, Medical | Soft, Smooth, Cost-effective |

| Meltblown | 20-200 | 0.3-1.5 | Air Filters, Masks, Medical Applications | Fine Fibers, High Filtration Efficiency |