Leave Your Message

-

CONTACT WhatsApp

CONTACT WhatsApp -

-

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT EMAIL

CONTACT EMAIL

In today's world, the demand for effective filtration solutions is higher than ever. Durable Nonwoven Filter Fabric plays a vital role in various applications. Its unique properties make it a preferred choice in multiple industries.

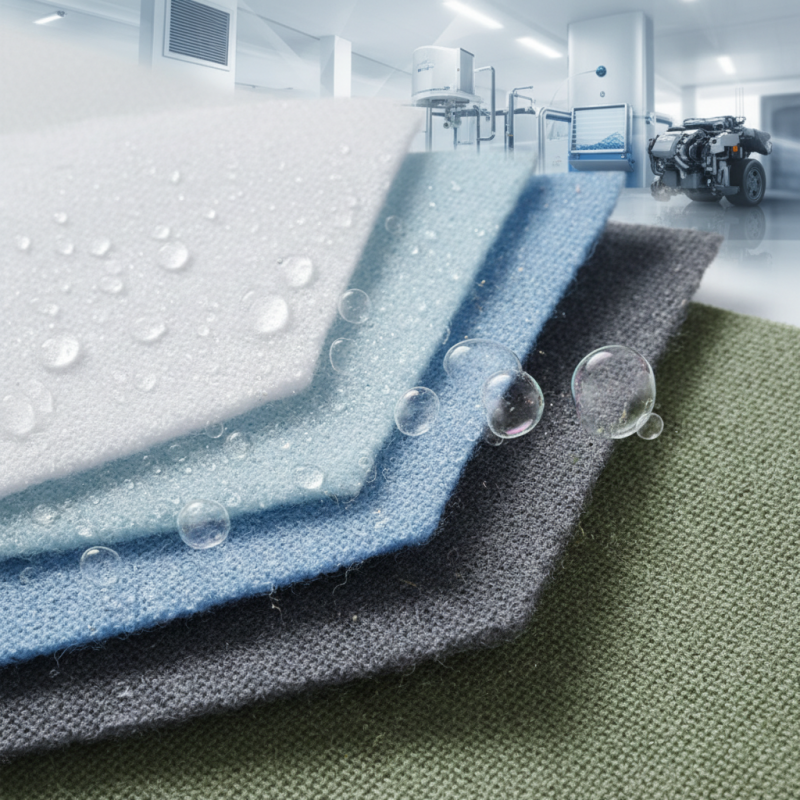

This fabric is known for its strength and versatility. Its nonwoven structure provides excellent filtration efficiency. Whether used in air, water, or industrial processes, it proves to be reliable. Many industries rely on these materials for effective filtration solutions.

However, not all durable nonwoven filter fabrics are created equal. Some may lack the necessary characteristics for specific applications. Selecting the right fabric is crucial; not all options perform the same. Therefore, understanding its uses and benefits can lead to more informed choices.

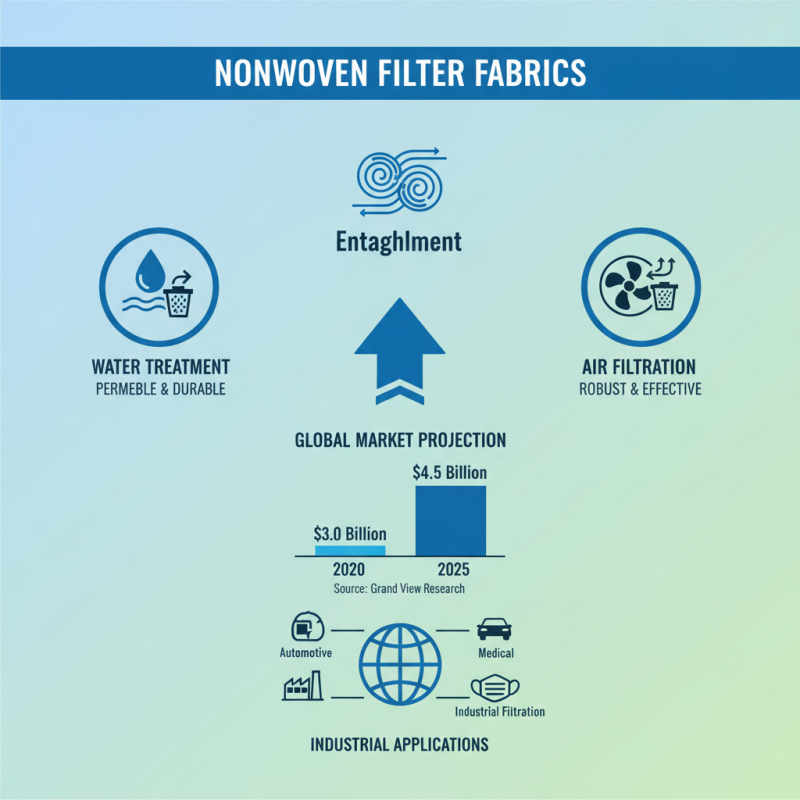

Nonwoven filter fabrics have gained significant traction in various industries due to their robustness and effectiveness. These textiles are created through a unique process that entangles fibers rather than weaving them. This results in a structure that is both permeable and durable, making them ideal for filtration applications. According to a report by Grand View Research, the global nonwoven filter market is projected to reach $4.5 billion by 2025, driven by increased demand in water treatment and air filtration.

One major benefit of nonwoven filter fabrics is their versatility. They can be tailored for different properties, such as oil absorption or airflow resistance. For instance, construction and civil engineering utilize these fabrics for sediment filtration in erosion control. In agriculture, they serve to protect crops by filtering out harmful elements while allowing essential air and moisture to pass through. However, one must consider the environmental impact of nonwoven fabrics, as improper disposal can lead to pollution.

**Tip:** When choosing a nonwoven filter fabric, assess your specific requirements. Consider factors like pore size and tensile strength. Achieving the right balance can enhance the performance of your application.

Another important point is that while these fabrics offer great benefits, they can be more expensive than traditional woven materials. A careful cost-benefit analysis is advisable before making a decision. Substituting nonwoven for woven may not always be the best choice.

Durable nonwoven filter fabrics stand out for their unique characteristics. These materials are lightweight yet strong, providing excellent filtration capabilities. The structure of nonwoven fabrics allows for high air permeability, ensuring efficient airflow. This trait is crucial in applications where ventilation is necessary, such as in HVAC systems. Additionally, these filters resist moisture well, making them suitable for diverse environments.

Another key characteristic is their chemical resistance. Nonwoven filters can withstand exposure to various substances without degrading. This property is essential in industrial applications, where exposure to chemicals is common. Furthermore, nonwoven fabrics are typically easier to produce than woven alternatives. The manufacturing process can lead to cost savings, though quality control remains a challenge. Flaws may go unnoticed, leading to variability in performance.

The versatility of durable nonwoven filters makes them widely used in many industries. From water treatment to air purification, their applications are vast. However, not all nonwoven fabrics are created equal. Differences in material composition can affect their overall effectiveness. Users must pay attention to specifications to avoid disappointment in performance. The balance between durability and efficiency should remain a key focus in future developments.

Nonwoven filter fabrics have gained popularity due to their versatile applications. One common use is in water filtration systems. These fabrics can capture impurities efficiently. They are often used in municipal water treatment plants. The porous structure allows for effective flow while blocking contaminants.

Another significant application is in air filtration. Industries frequently utilize nonwoven fabrics in HVAC systems. These fabrics help maintain air quality by trapping dust and allergens. They can be found in residential and commercial settings alike. Despite their durability, some users report varying success in filtration efficiency.

Lastly, nonwoven filter fabrics are used in agricultural applications. These materials serve as barriers against pests and dust in fields. They help in maintaining humidity levels while allowing air circulation. However, some gardeners have noted limitations in durability under harsh weather conditions. This raises questions about the long-term effectiveness of these fabrics in certain environments.

Nonwoven filter fabrics are transforming various industries. Their unique structure offers superior filtration, making them an excellent choice for many applications. In water treatment, they are effective in capturing sediments and pollutants. This leads to cleaner water, which is essential for health and environment.

Moreover, in the automotive sector, these materials help in air filtration systems. They ensure that harmful particles do not enter engines, improving efficiency. Simultaneously, they contribute to cabin air quality. However, manufacturers sometimes face challenges in balancing cost and performance.

In agriculture, nonwoven fabrics are used for weed control and improving soil health. These fabrics allow water and nutrients to penetrate while preventing weeds. Yet, some users report mixed results. They may not always provide the expected durability. Regular assessments and refining choices are essential for better outcomes.

When comparing nonwoven and woven filter fabrics, several factors emerge. Nonwoven fabrics offer unique advantages. They provide excellent filtration efficiency and durability. They resist wear and can endure harsher conditions. This makes them ideal for various applications.

Woven fabrics, however, have their strengths too. They often have a more structured appearance. They may provide better tensile strength in some cases. But they can be prone to fraying. Thus, considering the operating environment is crucial.

**Tips**: Assess your filtration requirements carefully. Consider factors like flow rates and particle sizes. Don’t overlook the environmental conditions.

Both types serve specific purposes. Nonwoven fabrics are often more cost-effective in bulk. Woven fabrics may last longer under certain stresses. Ultimately, the best choice hinges on your needs. Reflect on your project's unique demands. The wrong choice can lead to inefficiencies.

| Use | Material Type | Durability | Cost Effectiveness | Environmental Sustainability |

|---|---|---|---|---|

| Air Filtration | Polypropylene | High | Moderate | Biodegradable options available |

| Water Filtration | Polyester | Very High | High | Recyclable |

| Industrial Filtration | Nylon | Very High | Moderate | Limited options |

| Dust Collection | Cellulose | High | Low | Biodegradable |

| Oil Absorption | Polypropylene | High | High | Limited options |