What we know about spunbond nonwoven fabric?

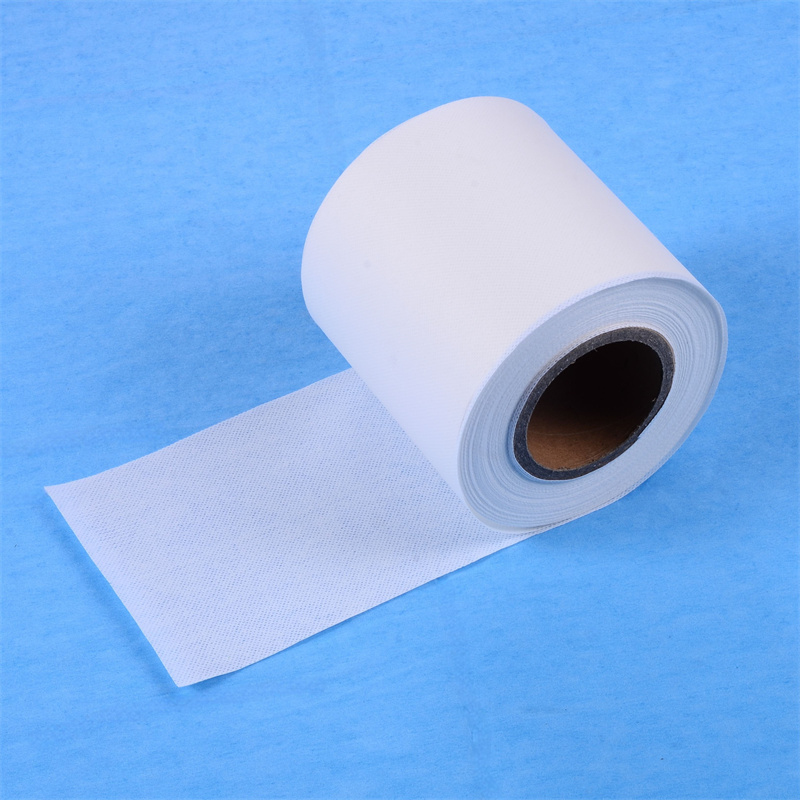

Spunbond Nonwoven fabric, as a traditional and mature process belonging to nonwoven fabric, still maintains a core position through continuous innovation and technological iteration.

Spunbond nonwoven fabric is mainly formed through four steps: melt extrusion, drawing, web laying and hot rolling.

First, polypropylene or polyester (PET) polymers are melted at high temperatures. Then, the melt is stretched into continuous filaments by high-pressure gas flow. The fibers randomly fall to form a uniform fiber web. Finally, the intersections of the fibers are pressed together by hot-rolling rollers.

Application scope

In the field of medical protection, surgical gowns/isolation suits are used. In the field of filtration, melt-blown layers are combined to achieve filtration efficiency. Other applications include the coating layers of hygiene products and furniture linings.

Multi Laminates

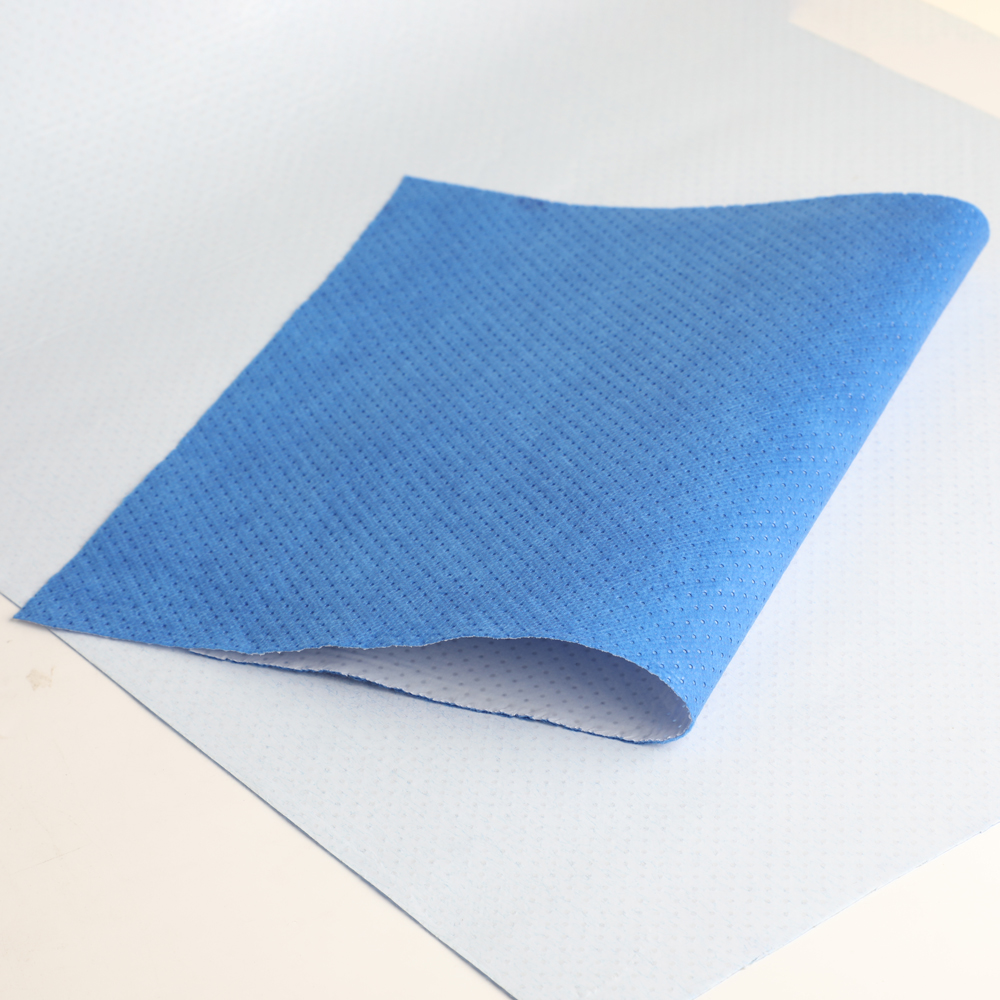

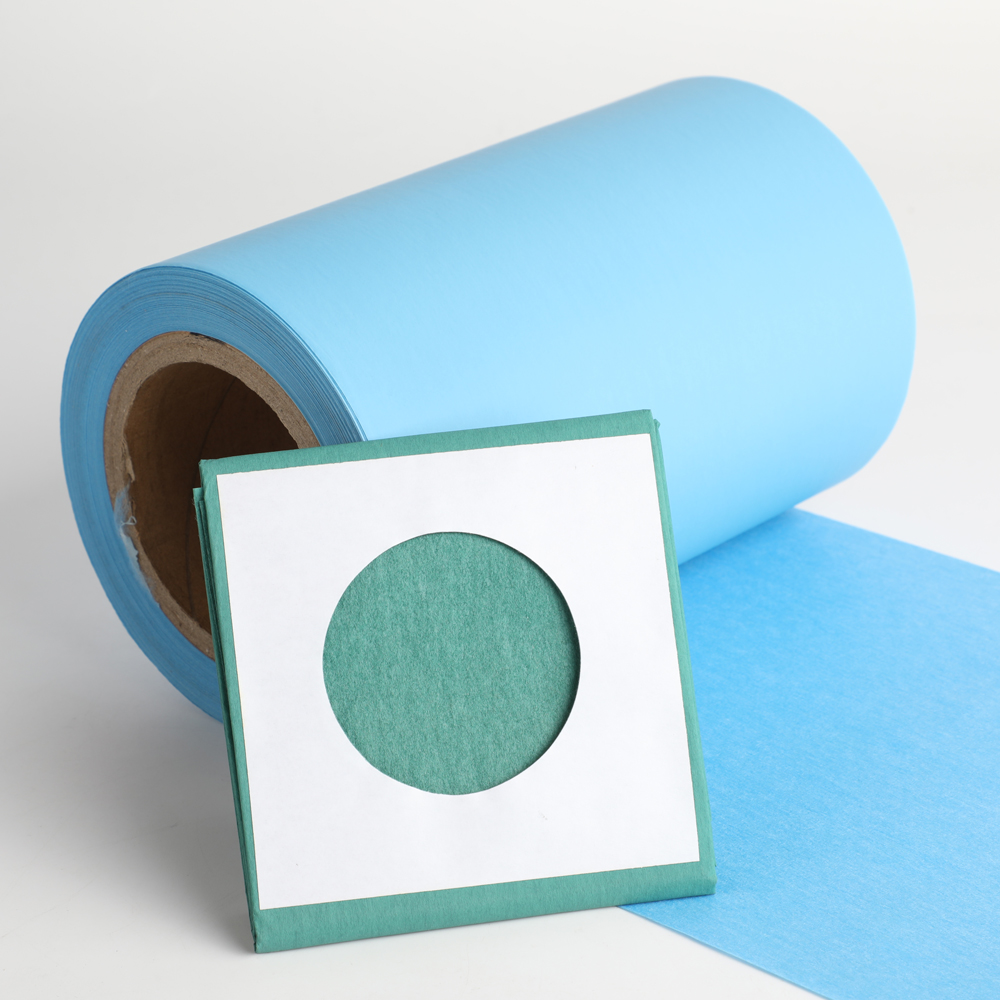

Multi Laminates Spunlace Nonwoven Laminates

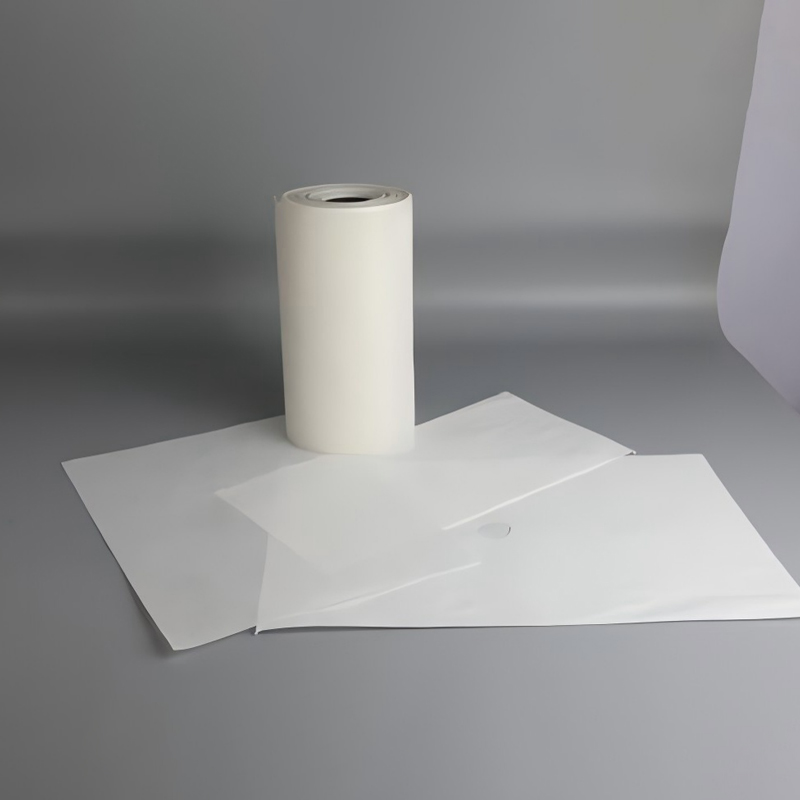

Spunlace Nonwoven Laminates Breathable Film Laminates

Breathable Film Laminates Viscose Laminates

Viscose Laminates Medical Tape Nonwoven

Medical Tape Nonwoven Filtration Nonwoven

Filtration Nonwoven Head Wear Nonwoven

Head Wear Nonwoven Medical Viscose Nonwoven

Medical Viscose Nonwoven Air Filter Media

Air Filter Media Liquid Filter Media

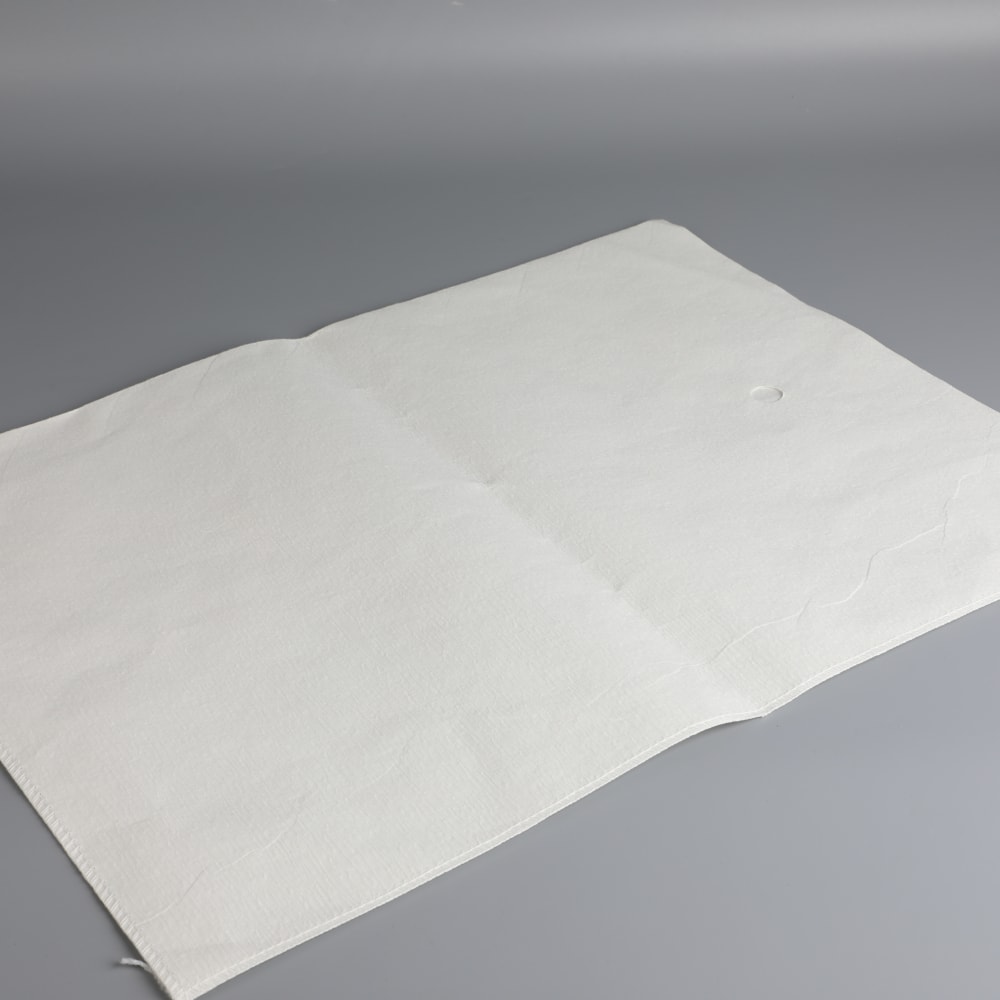

Liquid Filter Media Filter Envelope & Filter Sheet

Filter Envelope & Filter Sheet Breathable Film Laminates

Breathable Film Laminates Nonwoven Interlining

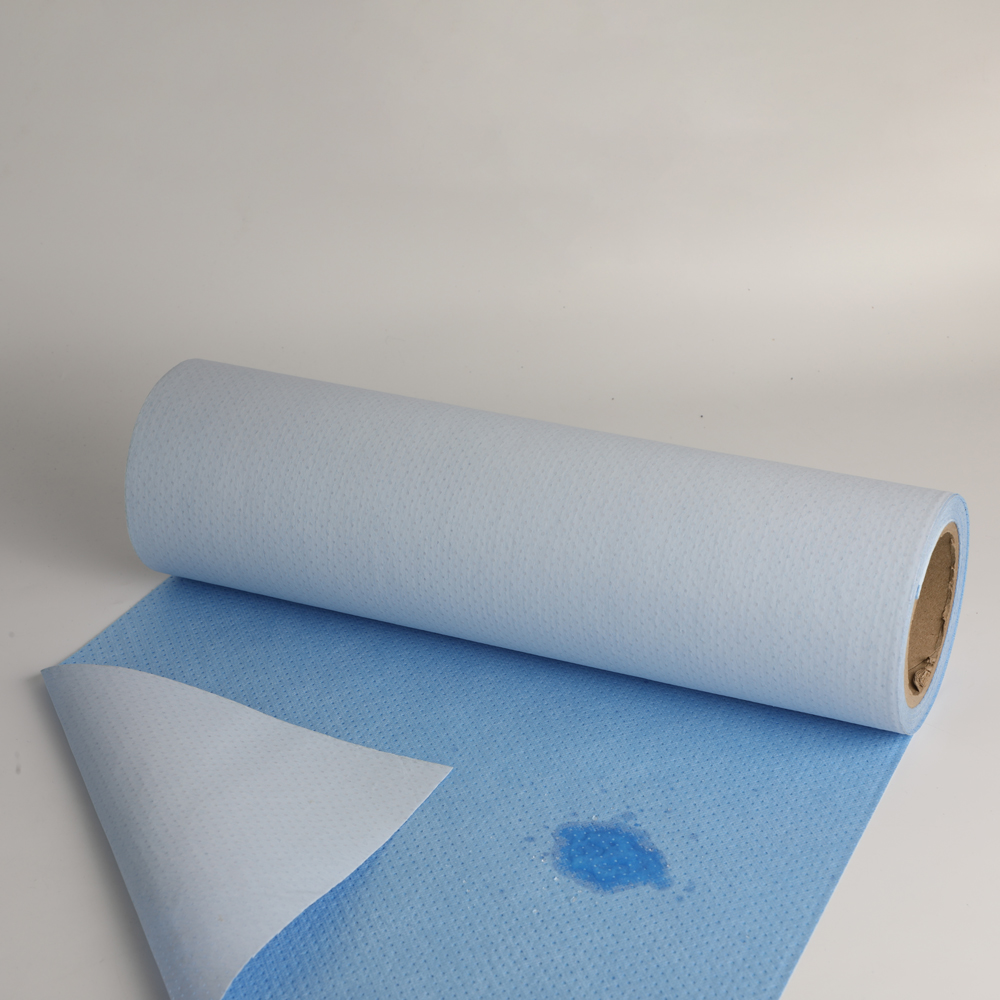

Nonwoven Interlining Fluid Repellent Woodpulp Spunlace Nonwoven

Fluid Repellent Woodpulp Spunlace Nonwoven Woodpulp Nonwoven Wipe

Woodpulp Nonwoven Wipe Nonwoven Cleaning Wipe

Nonwoven Cleaning Wipe Flame Retardant Nonwoven Fabric

Flame Retardant Nonwoven Fabric Anti-Bacterial Nonwoven

Anti-Bacterial Nonwoven